Gear Grinders

Shiuh Cheng introduced the most advanced grinding equipment from Germany to improve production capacity. Gear grinding is the core technology and skill of Shiuh Cheng Gear.

In 1994, we have purchased the first gear thread wheel grinding machine HOFLER H1000, and then in 2004, we have introduced the first gear profile grinding machine in Taiwan HOFLER RAPID 1500, and then successively introduced PFAUTER P2400G, HOFLER RAPID 800, HOFLER RAPID 2000, HOFLER RAPID 3000. So far Shiuh Cheng is the gear factory in Taiwan with the largest scale of profile grinding machines.

In pursuit of better product quality and service, Shiuh Cheng continues to import high-precision gear grinding equipment from Germany to continuously improve the quality of gear products.

The precision of Shiuh Cheng gears can reach JIS 0 and DIN 4 grades.

Shiuh Cheng Precision can quickly respond to shipping needs, and can also undertake a small number of customized orders. The precision of gear grinding can reach DIN4 level.

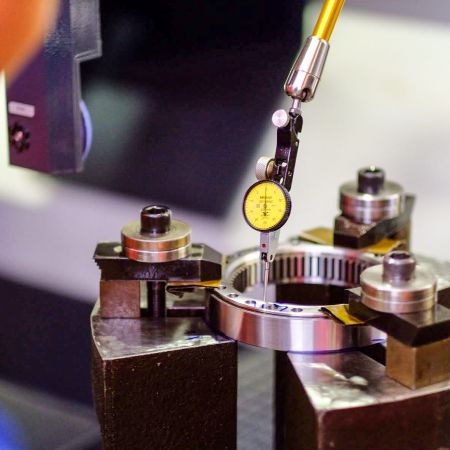

Using ultra-high-precision equipment, after the gear is ground, the workpiece can be directly measured on-line without dismantling it, ensuring a shortened delivery time.

Complicated tooth profiles can't beat us. From the knowledge of metal materials to heat treatment, our factory uses a strict quality control system to ensure stable quality.

Shiuh Cheng Gear Machining Capabilities

- External Gear: Max. O.D Ø3200mm

- Internal Gear: Min. I.D Ø100mm

- Module :1~ 50mm

- Cycloid Gear: Max. O.D Ø800mm

- HIRTH coupling Gear: Max. O.D Ø2000mm

Packing & Delivery

Shiuh Cheng provides gear customized services with excellent production efficiency.

In order to ensure the quality and safety of products to customers, Shiuh Cheng provides complete product protection packaging and inspection, so that the products can be safely delivered to your hands.

Our services are all over the world, and we sincerely invite buyers to cooperate, so that Shiuh Cheng can provide you with high-quality precision gears stably.

Precision Gear Common Material and Heat Treatment

| Classification | Taiwanese Name | JIS | JIS(Prev.) | DIN | AISI | Heat Treatment | |

|---|---|---|---|---|---|---|---|

| Carburization | QT、High Frequency | ||||||

| Carbon Steel | Medium-Carbon | S45C | 1045 | ◎ | |||

| Alloy Steel Carbon Steel | Green Cross | SCM415 | SCM21 | 15CrMo5 | 4115 | ◎ | |

| Green Cross | SCM420 | SCM22 | 18CrMo4 | 4118 | ◎ | ||

| Red Cross | SCM435 | SCM3 | 34CrMo4 | 4135 | ◎ | ||

| Red Cross | SCM440 | SCM4 | 42CrMo4 | 4140 | ◎ | ||

| White Cross | SNCM220 | SNCM22 | 21NiCrMo2 | 8620 | ◎ | ||

| Blue Cross | SNCM439 | SNCM8 | 40NiCrMo6 | 4340 | ◎ | ||

| 17CrNiMo6 | 4820 | ◎ |

| ||||

Precision Gear Grade

| Country | Type | Precision Grade | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U.S.A. | AGMA | 16 | 15 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 6 | |

| JAPAN | JIS | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||

| Germany | DIN | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

- Equipment