Gears For Defense Industry

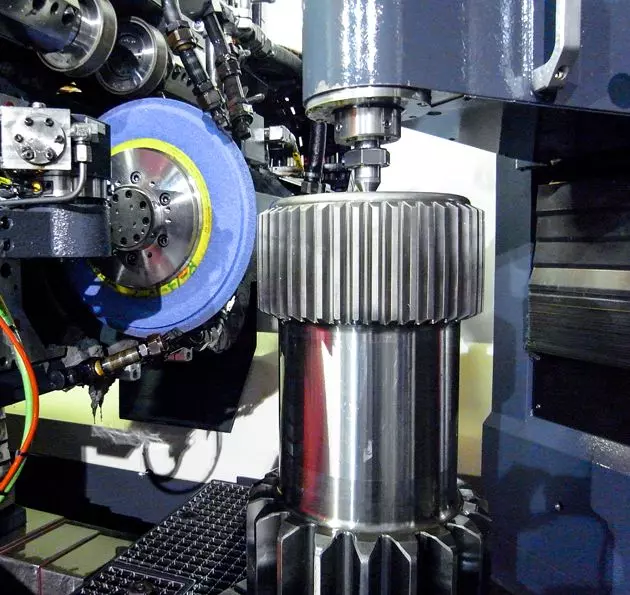

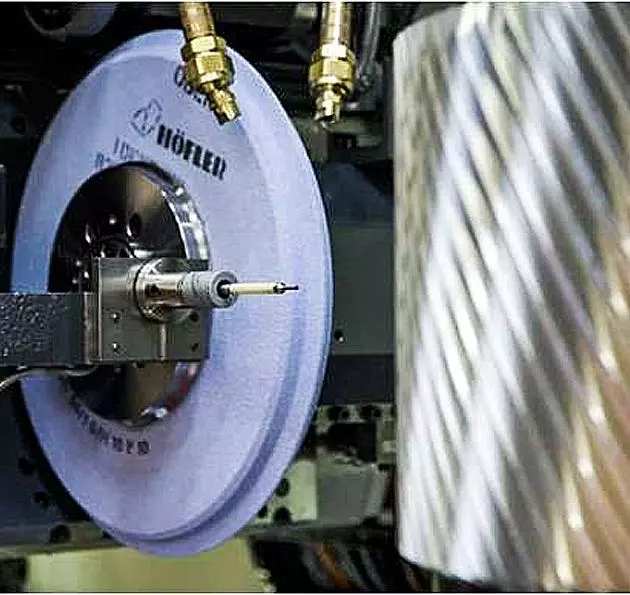

Precision gears used in defense systems, such as turrets and radar, play a critical role in high-precision, high-demand environments. These gears must maintain stable operation under extreme conditions, ensuring systems can perform tasks quickly and accurately. Precision gears in defense equipment require not only exceptional accuracy but also durability and reliability to withstand long-term operation and harsh environments. Shiuh Cheng GEAR has extensive experience in manufacturing precision gears for defense industry is deeply trusted by customers over the long term.

Conditions for making gears for Defense Industry

Requirements for Precision Gears in the Defense Industry:

High Precision Requirements:

Accurate Gear Profile and Tooth Spacing: Precision gears must feature extremely accurate gear profiles and tooth spacing to ensure precise positioning and responsiveness of radar and turrets, reducing errors.

Low Backlash Design: The gear backlash must be minimal to ensure fast response and precise control, particularly in weapon systems where millisecond-level accuracy is critical.

High Strength and Durability:

High Load Capacity: Gears must be capable of withstanding extremely high loads, ensuring they do not fail or deform under heavy equipment and high-speed operations.

Wear and Corrosion Resistance: Gear surfaces must have high wear resistance and corrosion resistance to withstand harsh environmental conditions, including high humidity, salt spray, and extreme temperatures.

Fatigue Resistance:

Long-Term Stable Operation: Gears must have excellent fatigue resistance to ensure they do not develop fatigue cracks or other damage during high-frequency, high-load, long-term operations.

Heat Treatment Requirements:

Surface Hardening: Heat treatment is used to increase surface hardness, enhancing the gears' wear resistance and deformation resistance, while maintaining enough toughness to handle sudden impacts or load changes.

Dynamic Balance and Low Noise:

Precision Dynamic Balance: Gears must maintain smooth operation at high speeds to reduce vibration and noise, which is especially important for the precise scanning of radar systems and the smooth rotation of turrets.

Lubrication and Maintenance:

Special Lubrication Requirements: Since defense equipment often operates under high load and high-temperature conditions, gears must be paired with high-performance lubricants to prevent overheating and wear, ensuring long-term, trouble-free operation.

These requirements ensure that precision gears in defense systems can operate reliably and long-term, meeting strict standards for accuracy, durability, and stability in critical equipment.

Gears For Defense Industry | JIS O & German DIN4 Level Precision Gear Increaser And Reducer | Shiuh Cheng Precision Gear Co., Ltd.

Located in Taiwan since 1994, Shiuh Cheng Precision Gear Co., Ltd. is a precision gear manufacturer. Main products, including precision Gears For Defense Industry, ground gears and gear increasers/reducers.

Founded in 1994, SHIUH CHENG PRECISION GEAR CO., LTD, with a pragmatic business philosophy as the foundation and a solid R & D capability as the backing, specializes in the design and manufacturing of high-precision gears and gear increaser/reducer.

SC GEAR has been offering customers high-quality gears and gearboxes since 1994, both with advanced technology and 40 years of experience, SC GEAR ensures each customer's demands are met.