Gears For Rubber and Plastic Industry

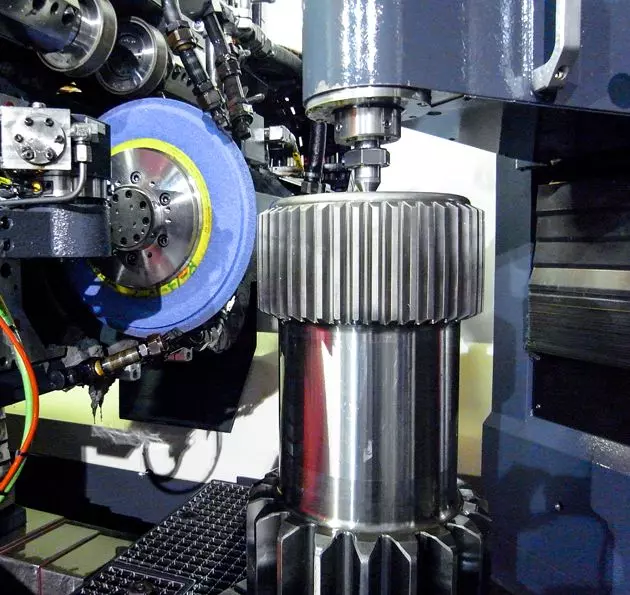

Precision gears used in the rubber and plastic industries play a key role in processing machinery, such as plastic molding machines, extruders, and other rubber and plastic processing equipment. These gears must maintain precise operation under high load and long-term use. Due to the specific demands of rubber and plastic production, these precision gears require excellent wear resistance, corrosion resistance, and good dynamic balance to ensure efficient production.

Conditions for making gears for Rubber and Plastic Industry

Requirements for Precision Gears in the Rubber and Plastic Industry:

Wear Resistance:

The rubber and plastic processing involves significant friction, so gears must have strong wear resistance to extend their service life and reduce maintenance needs.

Corrosion Resistance:

Since certain materials and additives in rubber and plastic products can be corrosive, gears must possess corrosion resistance to avoid damage caused by chemical reactions.

High Strength and Durability:

Precision gears must be able to withstand high loads and long operating hours, ensuring stable performance under high-pressure conditions without deformation or excessive wear.

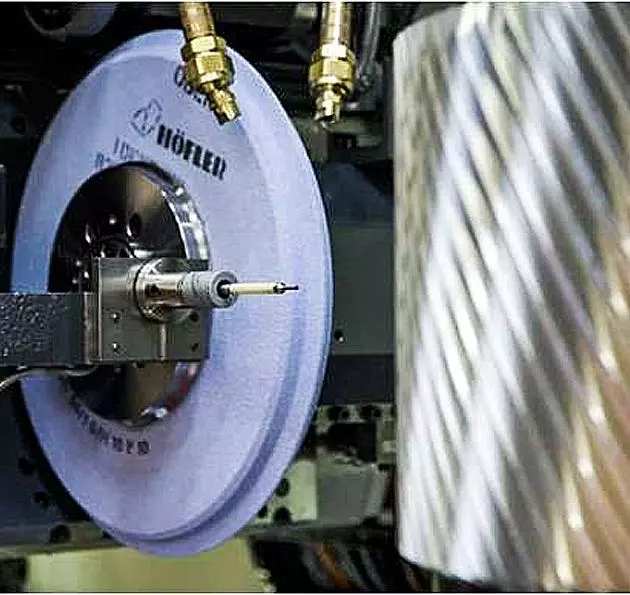

High Precision Requirements:

The high precision of machinery operation requires gears to have minimal backlash, ensuring precise motion control and minimizing mechanical errors.

Heat Treatment Requirements:

Surface hardening treatments are necessary to increase the gears' wear resistance and strength, ensuring they can operate for long periods under high temperatures and high pressures.

Lubrication Needs:

Since rubber and plastic processing generates high temperatures, gears must be equipped with appropriate lubrication systems to prevent overheating and damage from friction during long-term operation.

Noise and Vibration Control:

Precision gear design should minimize noise and vibration to improve the operational quality of the equipment and enhance production efficiency.

These requirements ensure that precision gears in the rubber and plastic industry can maintain long-term, efficient, and stable operation under harsh conditions, meeting the performance demands of production equipment.

Gears For Rubber and Plastic Industry | JIS O & German DIN4 Level Precision Gear Increaser And Reducer | Shiuh Cheng Precision Gear Co., Ltd.

Located in Taiwan since 1994, Shiuh Cheng Precision Gear Co., Ltd. is a precision gear manufacturer. Main products, including precision Gears For Rubber and Plastic Industry, ground gears and gear increasers/reducers.

Founded in 1994, SHIUH CHENG PRECISION GEAR CO., LTD, with a pragmatic business philosophy as the foundation and a solid R & D capability as the backing, specializes in the design and manufacturing of high-precision gears and gear increaser/reducer.

SC GEAR has been offering customers high-quality gears and gearboxes since 1994, both with advanced technology and 40 years of experience, SC GEAR ensures each customer's demands are met.