Gears For Machnine Tools

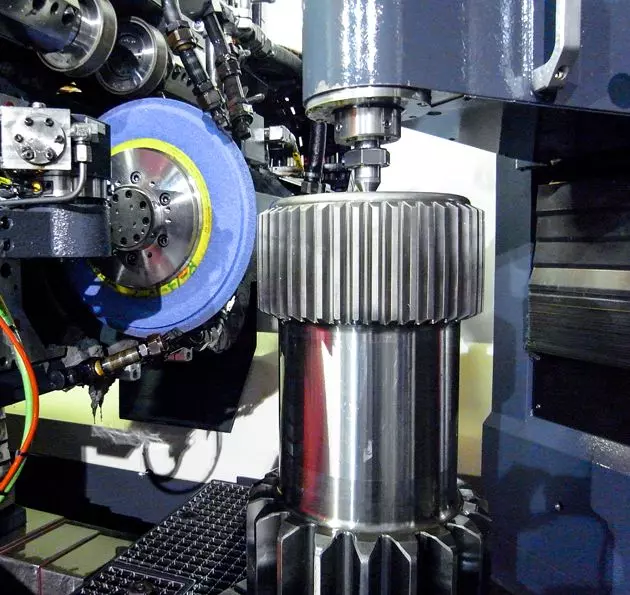

The gears used in machine tools have a series of specific requirements to ensure their performance, reliability, and lifespan, covering aspects such as materials, accuracy, and heat treatment. Shiuh Cheng GEAR has extensive experience in manufacturing precision gears for machine tools and is deeply trusted by customers over the long term.

Conditions for making gears for Machine tools

Key Points for Precision Gears in Machine Tools:

1.Material Requirements:

1.1High Strength and Toughness: Alloy steel or heat-treated steel is typically used to increase the load-bearing capacity and fatigue resistance of gears.

1.2Wear Resistance: Wear-resistant materials or surface hardening treatments are selected to reduce wear and extend the lifespan of the gears.

2.Manufacturing Precision Requirements:

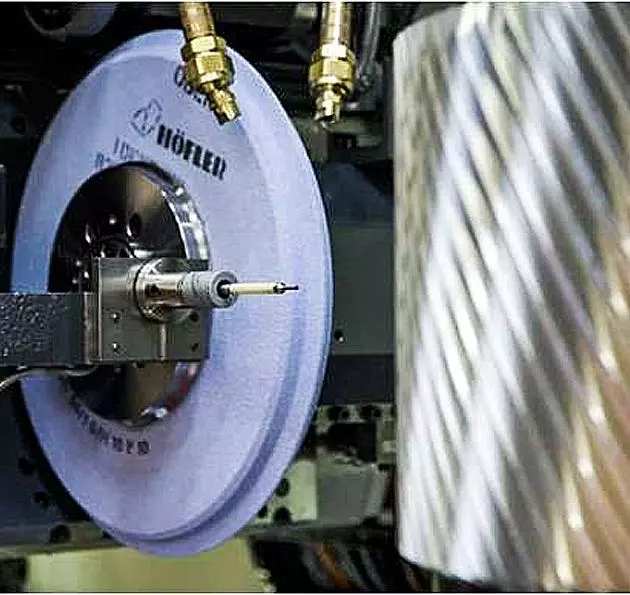

2.1High Precision Grade: Machine tool gears generally require high manufacturing precision to reduce noise and vibration during operation and to improve transmission efficiency.

2.2Gear Profile Accuracy: The accuracy of the gear profile is crucial for gear meshing quality, requiring precise machining and inspection.

2.3Heat Treatment Requirements:

2.4Surface Hardening: Processes such as carburizing, nitriding, or induction hardening increase gear surface hardness, improving wear resistance and the ability to resist fatigue cracks.

The process increases the hardness and wear resistance of the gears while maintaining sufficient toughness to prevent gear tooth breakage under high loads.

3.Lubrication Requirements:

A well-designed lubrication system or the selection of proper lubricants is essential to reduce friction, minimize wear, and prevent premature failure.

4.Noise and Vibration Control:

Optimized gear design and precise manufacturing help to minimize noise and vibration, improving the operational quality of the machine tool.

5.Service Life Requirements:

When designing and manufacturing gears, their expected service life under operating conditions must be considered, including load-bearing calculations and anticipated fatigue life.

These requirements ensure that gears perform excellently in high-speed, high-precision machine tool applications, meeting strict performance and reliability standards.

Gears For Machnine Tools | JIS O & German DIN4 Level Precision Gear Increaser And Reducer | Shiuh Cheng Precision Gear Co., Ltd.

Located in Taiwan since 1994, Shiuh Cheng Precision Gear Co., Ltd. is a precision gear manufacturer. Main products, including precision Gears For Machnine Tools, ground gears and gear increasers/reducers.

Founded in 1994, SHIUH CHENG PRECISION GEAR CO., LTD, with a pragmatic business philosophy as the foundation and a solid R & D capability as the backing, specializes in the design and manufacturing of high-precision gears and gear increaser/reducer.

SC GEAR has been offering customers high-quality gears and gearboxes since 1994, both with advanced technology and 40 years of experience, SC GEAR ensures each customer's demands are met.